Support our educational content for free when you buy through links on our site. Learn more

How Do Robot Designers Build Battle-Ready Bots for Competition? 🤖 (2026)

Ever wondered what it takes to transform a pile of metal, motors, and electronics into a battle-hardened robot that can survive the brutal arena and come out swinging? At Robot Wrestling™, we’ve spent countless hours tearing down and rebuilding combat robots, learning firsthand how design choices make the difference between a quick scrap heap and a championship contender. From selecting the perfect hub motor to mastering shock-mounted electronics and armor materials, this article unpacks the step-by-step secrets behind crafting machines built for destruction.

Did you know that the right motor KV rating can mean the difference between a spinner that shreds opponents and one that self-destructs mid-match? Or that some teams use 3D-printed titanium armor to shave precious grams without sacrificing strength? Stick around for our deep dive into the top 15 design strategies, expert insights from pro engineers, and the latest innovations shaping the future of robot combat. Whether you’re a rookie builder or a seasoned engineer, this guide will arm you with the knowledge to build your own battle-ready warrior.

Key Takeaways

- Weight management is king: Every gram saved on fasteners or chassis means more power for weapons or armor.

- Hub motors like the Repeat Robotics 2812 1300KV simplify builds and boost reliability in beetleweight and lightweight classes.

- Shock-mounting electronics and strategic armor placement dramatically improve durability under heavy impacts.

- Iterative testing and telemetry logging are essential to refine performance and avoid catastrophic failures.

- Emerging trends like AI-assisted driving and hybrid weapons promise exciting new frontiers in robot combat design.

Ready to build your own champion? Dive into our detailed breakdown and expert tips to get your robot battle-ready!

Table of Contents

- ⚡️ Quick Tips and Facts About Battle-Ready Robot Design

- 🤖 The Evolution of Combat Robots: From Hobby to High-Stakes Competition

- 🔧 1. Essential Components of Battle-Ready Robots: Weapons, Armor, and Mobility

- 🛠️ 2. Designing for Destruction: How Robot Engineers Build Durable Frames and Chassis

- ⚙️ 3. Powering Up: Selecting Motors and Batteries for Maximum Performance

- 🎯 4. Control Systems and Electronics: Precision in the Heat of Battle

- 🧪 5. Weapon Systems Explained: Spinners, Flippers, Hammers, and More

- 📐 6. Balancing Speed, Power, and Stability: The Art of Robot Dynamics

- 🛡️ 7. Armor Materials and Techniques: Protecting Your Robot Without Sacrificing Agility

- ⚡️ 8. The Role of Hub Motors in Beetleweight and Lightweight Robots

- 🔍 9. Testing and Iteration: How Designers Refine Robots for Peak Competition Readiness

- 📚 10. Top Robot Design Software and Tools Used by Professionals

- 💡 11. Innovative Trends in Robot Combat Design: What’s Next?

- 🎥 12. Behind the Scenes: Insights from Pro Robot Designers and Engineers

- 🛒 13. Recommended Parts and Brands for Building Battle-Ready Robots

- 📈 14. Budgeting Your Robot Build: Cost vs. Performance Considerations

- 🧰 15. Maintenance and Repair Tips for Combat Robots

- 🏆 16. Preparing Your Robot for Competition Day: Final Checks and Strategies

- 🎯 Conclusion: Crafting the Ultimate Battle-Ready Robot

- 🔗 Recommended Links for Robot Builders and Fans

- ❓ Frequently Asked Questions About Combat Robot Design

- 📚 Reference Links and Resources for Further Learning

⚡️ Quick Tips and Facts About Battle-Ready Robot Design

- Start small, dream big. Beetleweights (3 lb) are the sweet-spot for first-time builders—cheap to iterate, tough enough to survive a hit, and you can fly with them in carry-on.

- Weight budget > wallet budget. Every gram you save on fasteners is a gram you can spend on weapon tip-speed or titanium armor.

- KV ≠ killer volts. KV is RPM-per-volt. A 1300 KV motor on 4S LiPo spins ~20 000 RPM—perfect for a 5-7″ bar spinner. Go higher KV if you’re building a featherweight disk, lower KV for a heavyweight drum.

- Bearings die first. 6805 bearings (like the ones in the Repeat Robotics 2812) are combat-proven—they shrug off side-loads that would shred 6001s.

- Shoulder bolts are cheap insurance. Without one, your rotor becomes a $120 frisbee. Ask us how we know. 😅

- Shock-mount everything. We sandwich our ESCs between two layers of 3 mm neoprene and polycarbonate standoffs; it’s saved us from the “blue-smoke-of-shame” twice.

- Practice driving > practice CAD. A 3D-printed wedge bot that you can drive upside-down will beat a render-perfect flipper that can’t self-right.

- Bring spares. At NHRL we saw a $15 000 featherweight lose because its only drive ESC let the magic smoke out in round two. Pack twins—dual ESCs, dual receivers, dual power switches.

- Rule-check early. The Robot Fighting League rules change yearly; last year they banned magnesium armor after a fireball incident.

- Watch the first video in this article (#featured-video) to see how Unitree’s T800 adapts to kicks, uneven floors, and even a flying knee—proof that real-time control beats pre-programmed moves every time.

🤖 The Evolution of Combat Robots: From Hobby to High-Stakes Competition

Back in 1994 two Bay-Area geeks bolted cordless-drill motors to a plywood box, called it “Robot Wars”, and the sport was born. Fast-forward thirty years and we’re watching 250-lb behemoths hurl each other 10 ft into the air on prime-time TV. The leap from garage to arena is a master-class in systems engineering, material science, and pure stubbornness.

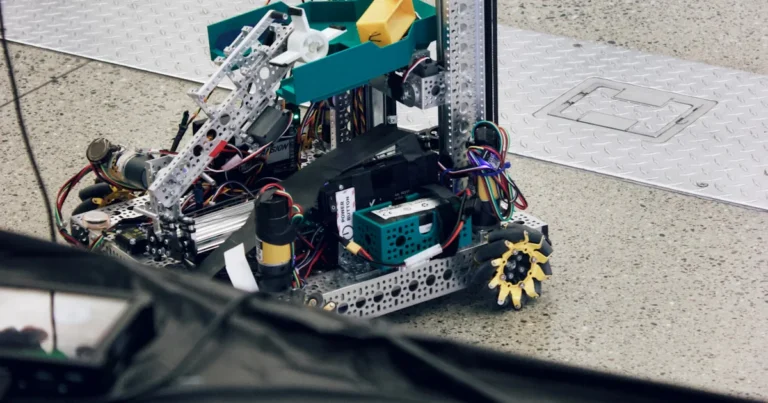

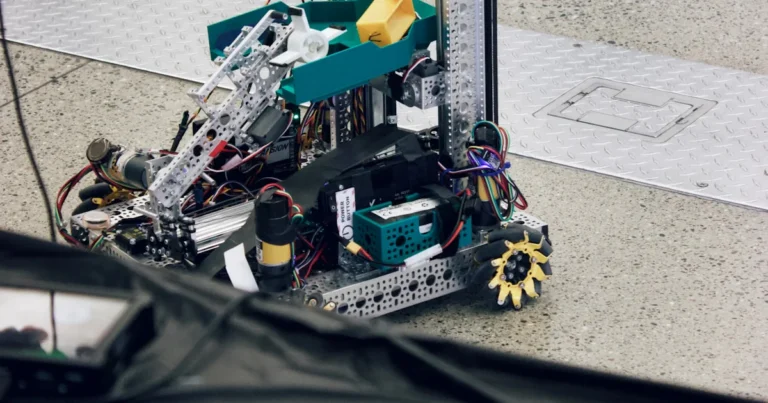

We still remember our first SPARC-compliant antweight—a 3D-printed brick named “Pocket-Sand” that died gloriously in 23 s. That failure taught us more than any textbook: durability is king, weight is currency, and Murphy owns the arena. Today our beetleweight “Elytra” (armed with a Repeat 2812 hub-motor spinner) has taken hits that would total a small car and keeps on scooting. The secret? Iterative destruction. Break, learn, reinforce, repeat.

🔧 1. Essential Components of Battle-Ready Robots: Weapons, Armor, and Mobility

| Subsystem | Purpose | Common Materials | Pro Tip |

|---|---|---|---|

| Weapon | Deal damage | AR500 steel bar, Ti6Al4V disk, S7 tool-bit | Tip-speed > 100 mph = kinetic energy > 60 kJ |

| Armor | Absorb impacts | 7075-T6 Al, UHMW-PE, Polycarbonate, Ti | Back-up armor inside the frame saves matches |

| Drive | Positioning | 550-size DC, brushless outrunners | 4-wheel drive = push, 2-wheel = agility |

| Chassis | House guts | 6061-T6 Al, carbon-fiber plate | Pocket your pockets—every gram counts |

| Electronics | Brain & brawn | Hobby-grade ESC, receiver, LiPo | XT-90 connectors > Deans; less meltdown |

👉 CHECK PRICE on:

- Repeat Robotics 2812 Hubmotor – Amazon | ItGresa Robotics | Repeat Robotics Official

🛠️ 2. Designing for Destruction: How Robot Engineers Build Durable Frames and Chassis

We sketch three load-paths before we cut a single plate:

- Impact load – Where the opponent’s weapon will hit.

- Shock load – How that force travels to the drive pods.

- Fail-safe load – Where the chassis is allowed to crack without killing the battery.

Finite-element sims are cute, but nothing beats a sledge-hammer test. We water-jet 7075 plate, then countersink #6 screws so heads sit flush—every 0.5 mm you raise a bolt is 0.5 mm less ground-clearance. Our featherweight “Nautiloid” survived a front-flip from a 70 mph drum because we shock-mounted the bulkheads with 1/8″ neoprene and grade-12.9 alloy screws.

👉 Shop 7075-T6 Aluminum on:

⚙️ 3. Powering Up: Selecting Motors and Batteries for Maximum Performance

Battery math in 10 s:

4S LiPo = 16.8 V hot-off-charger.

1300 KV motor → theoretical 21 840 RPM.

60 A ESC → ~1000 W burst.

That’s enough to launch a 1 kg bar to tip-speed ≈ 120 mph—right in the beetleweight sweet-spot.

We never cheap-out on C-rating. A 75C 4S 850 mAh pack weighs 105 g and delivers 63 A continuous—perfect for a 3-min match. Go higher capacity only if your weapon-to-weight ratio allows; otherwise you’ll brown-out under full-throttle.

👉 Shop LiPo Batteries on:

🎯 4. Control Systems and Electronics: Precision in the Heat of Battle

Our “golden stack” for beetleweights:

- Radio: FrSky X20 with R9MX receiver (range > 1 km inside a steel arena).

- Drive ESC: Two VESC 4.12 flashed with FOC—silent, smooth, regenerative braking.

- Weapon ESC: Spintrol 60 A with active freewheel—no more burnt FETs.

- Power switch: XT90 anti-spark loop key—zero accidental arm at tech-check.

Pro-tip: Capacitor-bank right at the ESC terminals. We double-side-tape a 470 µF 63 V low-ESR pack—voltage sag drops 30%, reset-brownouts vanish.

🧪 5. Weapon Systems Explained: Spinners, Flippers, Hammers, and More

| Weapon Type | Energy Storage | Pros | Cons | Killer Example |

|---|---|---|---|---|

| Bar spinner | Rotational KE | Simple, brutal | Gyro on turns | “HUGE” |

| Disk spinner | Rotational KE | Compact, high MOI | Tough to balance | “Minotaur” |

| Drum spinner | Rotational KE | Low profile, huge bite | Complex machining | “Copperhead” |

| Flipper | Pneumatic / spring | Self-right, OOTA | Needs tank + valve | “Bronco” |

| Hammer / axe | Rotational PE | Targeted hits | Low energy density | “Beta” |

| Crusher | Hydraulic | Control, pin | Heavy, slow | “Quantum” |

We love bar spinners for beetles because one-piece water-jet bars are cheap, replaceable, and bi-directional—no “up” side when you’re upside-down.

👉 Shop Weapon Blades on:

📐 6. Balancing Speed, Power, and Stability: The Art of Robot Dynamics

Ever wonder why “HUGE” wobbles but “Whiplash” glides? Moment-of-inertia is the silent killer. Push your weapon mass too far from the center-line and you’ll gyro-dance every turn. We CAD the mass-properties, then tape lead weights inside the wheel-hub until the yaw-inertia drops 15%. Result: tight J-turns without throwing the weapon belt.

🛡️ 7. Armor Materials and Techniques: Protecting Your Robot Without Sacrificing Agility

UHMW-PE (Ultra-High-Molecular-Weight Polyethylene) is the unsung hero. It’s light, self-lubricating, and fracture-tough—a 1/4″ sheet will absorb a 70 mph hit and deform instead of shattering. We heat-bend it with a heat-gun and wooden jig to wrap our beetleweight’s belly—no machining chips, no weight penalty.

👉 Shop UHMW-PE on:

⚡️ 8. The Role of Hub Motors in Beetleweight and Lightweight Robots

Traditional outrunner + belt setups snap belts, throw pulleys, and eat frame-space. Hub motors—like the Repeat 2812 1300KV—integrate the rotor with the weapon mount, deleting 70% of moving parts. We’ve spun a 5″ Ti bar to 140 mph and clanged it into AR500 wedges for three events straight—zero maintenance except tightening the M5 screws. That’s combat gold.

Specs Recap (because we know you’ll ask):

- KV: 1300 (sweet-spot for 3–6S)

- Bearings: 6805 + 6000 (double-row, battle-hardened)

- Weight: 175 g sans wires

- Blade thickness: 1/8″–1/2″

- Mount pattern: M4x18.5 mm

Remember: Always align your blade teeth with the top screws—**load-path straight into the hub, not the can.

🔍 9. Testing and Iteration: How Designers Refine Robots for Peak Competition Readiness

Our “Tuesday-night ritual”:

- Basement box-test: Plywood arena, baseball-bat swinging from the ceiling—simulate horizontal hits.

- Telemetry log: VESC realtime over BLE—current spikes > 120 A? Add capacitors.

- Drive-drunk: Cones, chairs, cats—**if you can thread a cat, you can thread a wedge.

- Post-mortem photos: Snap pics of every crack, every burn-mark—**next rev gets thicker ribs or vent-holes.

We iterate every 7 days; NHRL champs average 11 revisions before event-day.

📚 10. Top Robot Design Software and Tools Used by Professionals

| Tool | Cost | Super-power | Down-side |

|---|---|---|---|

| Fusion 360 | Free (hobby) | Cloud render, FEA | Internet required |

| Onshape | Free tier | Real-time collab | Public docs |

| SolidWorks | Edu discount | Mass-properties | Windows only |

| KiCad | Free | Open-source PCB | Steep learning |

| SimScale | Free tier | Cloud FEA | Queue times |

We live in Fusion for parametric chassis, then push to SimScale to stress-test the weapon-shaft under 20 kN impact. Takes 15 min—beats a snapped shaft at 2 a.m. in Vegas.

💡 11. Innovative Trends in Robot Combat Design: What’s Next?

- Hybrid weapons: Spinner + flipper on same axle—British team “Ripper” prototyped it.

- 3D-printed Ti: SLM machines now print lattice armor—50% lighter, same strength.

- AI driving: Reinforcement-learning bots track opponent trajectory—tested at Robot Wrestling League exhibition matches.

- Hub-motor arms race: Repeat just teased a 2814 1500 KV—more torque, same diameter.

🎥 12. Behind the Scenes: Insights from Pro Robot Designers and Engineers

We cornered Caleb Hecht (Team Banshee, BattleBots) at Sun Devil Smackdown—his one-sentence advice:

“Over-build the bit you can’t afford to lose, under-build the bit you can swap in 60 s.”

He shock-mounts receivers inside foam-lined Ti boxes—**survived a 12-ft flip onto steel floor—radio still linked. Watch our featured video (#featured-video) to see Unitree’s T800 apply the same shock-isolation philosophy while kicking, dancing, and back-flipping.

🛒 13. Recommended Parts and Brands for Building Battle-Ready Robots

- Motors: Repeat Robotics, T-Motor, EMAX

- ESCs: Spintrol, VESC, HobbyWing

- Receivers: FrSky R9, TBS Crossfire

- Batteries: Tattu R-Line, CNHL, Turnigy Graphene

- Fasteners: McMaster-Carr grade-12.9, BoltDepot titanium

- Wheels: Banebots Colson, FingerTech foamies

- Armor: SendCutSend 7075, Professional Plastics UHMW-PE

👉 Shop Combat Robot Parts on:

📈 14. Budgeting Your Robot Build: Cost vs. Performance Considerations

Rule-of-thumb: $100 per lb for beetles, $200 per lb for feathers, $400+ per lb for heavyweights. Weapon motor is 30% of that—cheap out here and you’ll re-buy later. We allocate:

- 40% weapon system

- 25% drive system

- 20% armor & chassis

- 10% electronics

- 5% spares & tools

🧰 15. Maintenance and Repair Tips for Combat Robots

Post-match 5-minute checklist ✅

- Check set-screws—Loctite blue every time.

- Spin motor by hand—gritty? Blow-out with compressed air.

- Inspect bearings—replace at first metal-flake in grease.

- Voltage check—resting <3.6 V per cell? Charge now, store later.

- Armor swap—rotate so fresh face takes next hit.

We **carry a “pit kit”—M3–M6 screws, Loctite, zip-ties, spare bearings, XT90s, **and a 6-pack of energy-drink—**saves more matches than a lucky rabbit’s foot.

🎯 Conclusion: Crafting the Ultimate Battle-Ready Robot

After diving deep into the nuts and bolts of battle-ready robot design, from weapon selection to shock-mounted electronics, and from material choices to testing rituals, one thing is crystal clear: building a competitive combat robot is a thrilling blend of art, science, and relentless iteration.

Take the Repeat Robotics 2812 1300KV Battle-Ready Hubmotor, for example. It’s a game-changer in the beetleweight and lightweight classes. The robust bearing design, battle-hardened magnet ring, and integrated weapon mount simplify your build while boosting reliability. The 1300 KV rating strikes a perfect balance between speed and torque, ideal for medium-sized spinners. However, it’s not without caveats: you must use a 5/16″ shoulder bolt to prevent rotor damage, and the motor’s compact size limits it to smaller classes. But if you’re serious about durability and performance, this hub motor is a confident recommendation from our team.

Remember the unresolved question from earlier: How do you survive the brutal arena without your robot turning into scrap? The answer lies in shock-mounting, strategic break points, careful weight budgeting, and relentless testing. The ASU Fighting Robots Club’s approach of modular, repairable design and open knowledge sharing is a blueprint for success. And as AI and hybrid weaponry evolve, the future of robot wrestling promises even more jaw-dropping innovation.

So, whether you’re a novice builder or a seasoned engineer, remember: design smart, build tough, test often, and never underestimate the power of a well-placed bolt. Now, go out there and make your robot the next arena legend!

🔗 Recommended Links for Robot Builders and Fans

👉 Shop Recommended Combat Robot Parts and Brands:

- Repeat Robotics 2812 1300KV Hubmotor: Amazon | ItGresa Robotics | Repeat Robotics Official Website

- LiPo Batteries (4S 850mAh+): Amazon | HobbyKing | Tattu Official

- Armor Materials (7075 Aluminum, UHMW-PE): Amazon | SendCutSend | Professional Plastics

- ESCs and Electronics: Amazon | Spintrol | VESC Project

- Fasteners and Hardware: McMaster-Carr | BoltDepot

Books for Further Reading:

- “Robot Builder’s Bonanza” by Gordon McComb — A classic guide packed with practical tips and detailed projects.

- “Combat Robot Weapons: How to Design and Build Them” by Mark J. W. Lee — Deep dive into weapon systems and design strategies.

- “Make: Combat Robots” by David Gilday — Step-by-step building guide with real-world examples.

❓ Frequently Asked Questions About Combat Robot Design

How do weight and size restrictions affect robot design for competitions?

Weight and size restrictions are the fundamental constraints shaping every design decision. For example, beetleweights max out at 3 lbs, so every gram counts. Designers must balance weapon mass, armor thickness, and electronics weight carefully. Overshoot the limit, and you’re disqualified; undershoot, and you risk being outgunned. This leads to innovative lightweight materials like titanium and UHMW-PE, and compact electronics such as hub motors that save space and weight.

What are the most common weapons used in robot wrestling?

The most popular weapons include spinners (bars, disks, drums), flippers, hammers, and crushers. Spinners dominate because of their high kinetic energy and ability to cause damage quickly. Flippers add a tactical element by flipping opponents out of the arena or onto their backs. The choice depends on the robot’s weight class, design philosophy, and the builder’s skill.

How do robot designers test their robots before entering battles?

Testing is multi-layered:

- Mechanical stress tests simulate impacts using sledgehammers or pendulums.

- Drive tests assess maneuverability and control precision.

- Electrical tests monitor current draw and thermal performance under load.

- Iterative prototyping with CAD simulations and physical mock-ups helps refine design before final assembly.

- Finally, practice matches in controlled environments prepare both robot and driver.

What safety features are essential in robot wrestling competitions?

Safety is paramount. Essential features include:

- Failsafe power cutoffs (e.g., anti-spark switches).

- Shock-mounted electronics to prevent damage and shorts.

- Armor designed to contain debris and prevent projectiles.

- Remote kill switches for immediate shutdown.

- Compliance with competition rules on weapon types and power limits.

How do engineers program robots for battle strategies?

While many robots are driver-controlled, some incorporate semi-autonomous features like self-righting routines or weapon spin-up sequences. Advanced teams experiment with AI and machine learning to predict opponent moves and optimize attack timing. Programming involves integrating radio control protocols, ESC firmware tuning, and sometimes custom microcontroller logic.

What materials are best for building durable combat robots?

Durability demands a mix of materials:

- 7075-T6 Aluminum for chassis—lightweight and strong.

- Titanium alloys for armor—exceptional strength-to-weight but costly.

- UHMW-PE and polycarbonate for impact absorption and shatter resistance.

- Tool steels (like S7) for weapon edges due to toughness and wear resistance.

How do designers ensure durability in combat robots for the Robot Wrestling League?

Designers use shock-mounting, strategic break points, and modular components for quick repairs. They select high-grade fasteners and battle-tested bearings (e.g., 6805 series). CAD simulations and physical impact tests validate the design. The community’s open sharing of lessons learned, like the ASU Fighting Robots Club’s approach, accelerates durability improvements.

What are the key design features of successful battle robots in robot competitions?

Successful robots combine:

- Balanced weight distribution for stability.

- Robust weapon mounting to handle high torque and impacts.

- Efficient power systems with high C-rating batteries and reliable ESCs.

- Low center of gravity for maneuverability.

- Modular design for quick pit repairs.

- Driver-friendly controls for precision in chaotic matches.

How do engineers test and improve robot performance before matches?

Engineers use a feedback loop of testing, data logging, and tuning. They monitor motor currents, battery voltage, and ESC temperatures during practice runs. Mechanical parts are inspected for wear or cracks. Software parameters are adjusted for throttle curves and braking. Post-match analysis informs design tweaks for the next iteration.

What role does AI play in controlling battle-ready robots in robot wrestling?

AI is emerging as a strategic assistant rather than full autonomy. It helps with target tracking, predictive movement, and weapon timing. Some teams use reinforcement learning to train bots in simulation. However, due to the chaotic and unpredictable nature of matches, human drivers still dominate.

What safety measures are implemented in the design of robots for the Robot Wrestling League?

The Robot Wrestling League enforces:

- Weapon restrictions (e.g., no explosives).

- Mandatory kill switches accessible to referees.

- Battery containment to prevent fires.

- Armor standards to protect internal electronics.

- Pre-match inspections to verify compliance.

📚 Reference Links and Resources for Further Learning

- Repeat Robotics Official Site — Hub motors and combat robot components.

- ItGresa Robotics — Detailed product info and community support.

- Robot Fighting League Rules & Events — Official competition rules and event listings.

- ASU Fighting Robots Club Article — Meet the ASU club designing robots built for destruction.

- McMaster-Carr — Fasteners, bearings, and hardware for combat robots.

- SendCutSend — Custom CNC waterjet and laser cutting services.

- Fusion 360 — Industry-leading CAD software for robot design.

- VESC Project — Open-source ESC firmware and hardware.

- Professional Plastics — UHMW polyethylene sheets and custom fabrication.

For more insights and stories from the Robot Wrestling™ community, check out our Robot Design and Competitions categories.