Support our educational content for free when you buy through links on our site. Learn more

What Materials Are Best for Building a Robot Wrestling Frame? 🛠️ (2025)

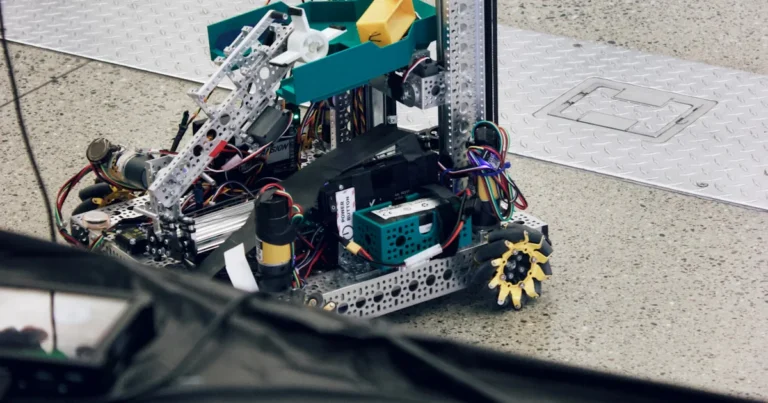

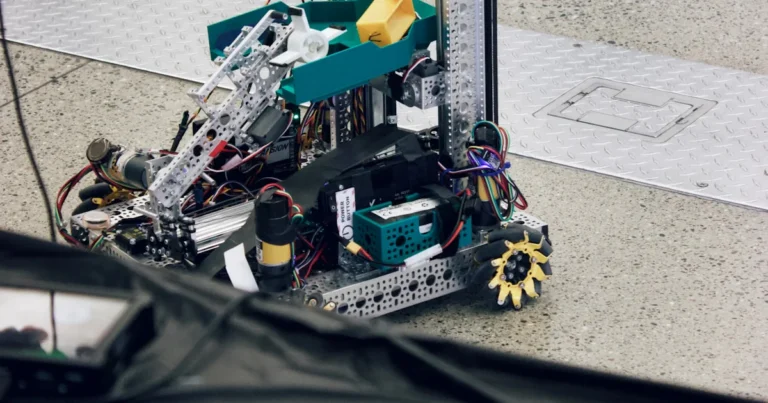

Building a robot wrestling frame isn’t just about slapping some metal together and hoping for the best. It’s a high-stakes game of strength, weight, and resilience—where every ounce and every weld counts. Did you know that the choice of frame material can make or break your bot’s chances in the arena? In fact, some of the combat-league/”>top Robot Wrestling League™

champions swear by a secret blend of materials that balance lightweight agility with unyielding toughness.In this article, we’ll take you on a deep dive through the 7 best materials for robot wrestling frames, from the trusty 6061-T6 aluminum to the exotic Grade 5 titanium and cutting-edge carbon fiber composites. We’ll share insider tips from our team of robot designers and engineers, reveal the pros and cons of each material, and help you decide which one fits your robot’s weight class, budget, and battle style. Ready to discover the secret sauce behind the toughest frames in robot wrestling? Let’s get started!

Key Takeaways

- Aluminum alloys (6061-T6 and 7075-T6) offer the best balance of strength and weight for most builders.

- Steel alloys, especially chromoly (4130), provide unmatched durability but add weight.

- Titanium alloys deliver elite strength-to-weight ratios but require specialized skills and budget.

- Composite materials like carbon fiber and UHMW-PE are lightweight and impact-resistant but can be brittle or costly.

- Your choice should align with your robot’s weight class, fabrication capabilities, and budget.

- Combining materials strategically often yields the best performance in the arena.

Ready to build a frame that can take a hit and keep on fighting? Keep reading to find out which materials will give you the winning edge!

Table of Contents

- ⚡️ Quick Tips and Facts

- 🤖 The Steel Cage Saga: A Brief History of Robot Wrestling Frame Evolution

- 🏗️ The Foundation of Fury: Why Your Robot Frame Material Matters Most

- 🛠️ The Contenders: Top Materials for Robot Wrestling Frames

- ⚙️ Beyond the Material: Design Principles for an Indestructible Frame

- 💰 The Bottom Line: Budgeting for Your Battle-Ready Frame

- 🔧 Fabrication Finesse: Manufacturing Your Frame Components

- 🚧 Assembly Line Antics: Putting Your Frame Together

- 🧪 The Proving Grounds: Testing Your Frame’s Mettle

- 🏆 Victory Lap: Enjoying Your Robot and Planning the Next Evolution

- Conclusion: Forging Your Path to Robot Wrestling Glory

- Recommended Links: Your Arsenal of Robot Building Resources

- FAQ: Your Burning Questions About Robot Frame Materials Answered

- Reference Links: Dive Deeper into Material Science

Quick Tips and Facts

If you’re looking to build a robot wrestling frame, you’re probably wondering what materials are best for the job. Before we dive into the details, here are some quick tips and facts to get you started:

- Aluminum alloys like 6061-T6 and 7075-T6 are popular choices for robot frames due to their high strength-to-weight ratio.

- Steel alloys, such as mild steel and high-strength low-alloy (HSLA) steel, offer excellent durability and resistance to impact.

- Titanium alloys are extremely strong and lightweight, making them ideal for high-performance robots.

- Composite materials like carbon fiber and ultra-high molecular weight polyethylene (UHMW-PE) are increasingly popular for robot frames due to their unique properties. For more information on robot wrestling leagues and organizations, check out our article on Are There Any Robot Wrestling Leagues or Organizations I Can Join? 🤖.

The Steel Cage Saga: A Brief History of Robot Wrestling Frame Evolution

The evolution of robot wrestling frames has been a wild ride, with various materials and designs being tested and refined over the years. From the early days of robot combat to the current high-tech machines, the development of robot frames has been shaped by innovation, experimentation, and competition. According to Robot Wrestling League, the first robot wrestling competitions were held in the 1990s, with robots made from steel, aluminum, and other materials. As the sport gained popularity, robot designers and engineers began to experiment with new materials and techniques, leading to the development of more advanced and specialized robot frames. For example, the use of titanium alloys in robot frames has become increasingly popular in recent years due to their high strength-to-weight ratio and corrosion resistance. As noted by NASA, titanium alloys are also used in aerospace applications due to their unique properties.

The Foundation of Fury: Why Your Robot Frame Material Matters Most

When it comes to building a robot wrestling frame, the material you choose can make all the difference. The frame is the foundation of your robot, and its strength, durability, and weight can affect your robot’s performance and overall success. Here are some key factors to consider when selecting a material for your robot frame:

- Strength-to-weight ratio: A higher strength-to-weight ratio means your robot can be stronger and lighter, giving you a competitive edge.

- Durability: A durable material can withstand impacts and last longer, reducing the need for repairs and maintenance.

- Weight: A lighter robot can be faster and more agile, but may sacrifice strength and stability.

- Cost: Different materials have varying costs, and your budget can limit your options. For more information on robot design and construction, check out our article on Robot Design.

Balancing Act: Weight, Durability, and Cost Considerations for Your Combat Robot Frame

When choosing a material for your robot frame, you need to balance competing factors like weight, durability, and cost. Here are some trade-offs to consider:

- Aluminum alloys are lightweight and corrosion-resistant, but may lack durability and be more expensive than steel.

- Steel alloys are strong and durable, but can be heavy and prone to corrosion.

- Titanium alloys are extremely strong and lightweight, but are very expensive and can be difficult to work with.

- Composite materials can offer unique properties like high strength-to-weight ratio and impact resistance, but can be expensive and require specialized manufacturing techniques. As noted by McMaster-Carr, the choice of material for your robot frame depends on your specific needs and priorities.

Sizing Up the Competition: How Robot Weight Classes Influence Frame Material Choices

The weight class of your robot can significantly impact your choice of frame material. Here are some general guidelines for different weight classes:

- Lightweight robots (under 10 pounds): Aluminum alloys or composite materials may be suitable due to their high strength-to-weight ratio.

- Middleweight robots (10-30 pounds): Steel alloys or titanium alloys may be preferred for their balance of strength and durability.

- Heavyweight robots (over 30 pounds): Steel alloys or high-strength composite materials may be necessary for their exceptional strength and stability. For more information on robot competitions, check out our article on Competitions.

The Contenders: Top Materials for Robot Wrestling Frames

Here are some of the top materials for robot wrestling frames, along with their key characteristics and applications:

1. Aluminum Alloys: The Lightweight Champion’s Choice

Aluminum alloys are a popular choice for robot frames due to their high strength-to-weight ratio, corrosion resistance, and ease of fabrication.

- 6061-T6 aluminum: A heat-treated alloy with good machinability and weldability, making it suitable for chassis and outer frame supports.

- 7075-T6 aluminum: A stronger and more durable alloy than 6061-T6, but harder to form and weld. For more information on aluminum alloys, check out Aluminum.org.

A. 6061-T6 Aluminum: The Workhorse of the Arena

6061-T6 aluminum is a versatile and widely used alloy for robot frames. Its good machinability and weldability make it easy to fabricate and assemble. According to Instructables, 6061-T6 aluminum is a popular choice for robot frames due to its balance of strength, durability, and cost.

B. 7075-T6 Aluminum: When Every Ounce of Strength Counts

7075-T6 aluminum is a high-strength alloy that offers excellent durability and resistance to impact. However, it can be harder to form and weld than 6061-T6. As noted by Chief Delphi, 7075-T6 aluminum is a good choice for robots that require exceptional strength and stability.

C. Anodizing and Surface Treatments: Boosting Aluminum’s Resilience

Anodizing and surface treatments can enhance the corrosion resistance and wear resistance of aluminum alloys. This can be especially important for robots that operate in harsh environments. For more information on anodizing and surface treatments, check out Finishing.com.

2. Steel Alloys: The Unyielding Fortress

Steel alloys are a popular choice for robot frames due to their high strength, durability, and cost-effectiveness.

- Mild steel (1018, A36): A budget-friendly alloy with good weldability and machinability, making it suitable for chassis and frame supports.

- High-strength low-alloy (HSLA) steel: A stronger and more durable alloy than mild steel, with improved weldability and resistance to corrosion. For more information on steel alloys, check out Steel.org.

A. Mild Steel (1018, A36): The Budget Brawler’s Best Friend

Mild steel is a cost-effective alloy that offers good weldability and machinability. However, it may lack durability and be prone to corrosion. According to Huge BattleBots, mild steel is a good choice for robots that require high strength and durability without breaking the bank.

B. High-Strength Low-Alloy (HSLA) Steel: Toughness Without the Bulk

HSLA steel is a stronger and more durable alloy than mild steel, with improved weldability and resistance to corrosion. However, it can be more expensive and harder to fabricate. As noted by Robot Wrestling League, HSLA steel is a good choice for robots that require exceptional strength and stability.

C. Chromoly (4130 Steel): The Pro’s Pick for Ultimate Strength-to-Weight

Chromoly steel is a high-strength alloy that offers excellent durability and resistance to impact. However, it can be expensive and require specialized fabrication techniques. For more information on chromoly steel, check out AISI.

3. Titanium Alloys: The Elite’s Exotic Edge

Titanium alloys are a high-performance material that offers exceptional strength, lightweight, and corrosion resistance.

- Grade 5 (Ti-6Al-4V): A high-strength alloy with excellent durability and resistance to impact, making it suitable for high-performance robots. For more information on titanium alloys, check out Titanium.org.

A. Grade 5 (Ti-6Al-4V): The Pinnacle of Performance

Grade 5 titanium alloy is a high-strength material that offers excellent durability and resistance to impact. However, it can be very expensive and require specialized fabrication techniques. According to NASA, Grade 5 titanium alloy is a good choice for robots that require exceptional strength and stability.

B. Challenges and Considerations for Titanium Fabrication

Titanium alloys can be challenging to fabricate due to their high strength and low thermal conductivity. Specialized fabrication techniques and tools may be required. As noted by Instructables, titanium alloys are a good choice for robots that require high performance and exceptional strength.

4. Composites: The Future of Robot Armor?

Composite materials are a new frontier in robot frame design, offering unique properties like high strength-to-weight ratio, impact resistance, and corrosion resistance.

- Carbon fiber: A high-strength and lightweight material with excellent durability and resistance to impact.

- UHMW-PE (Ultra-High Molecular Weight Polyethylene): A high-strength and impact-resistant material with excellent durability and corrosion resistance. For more information on composite materials, check out CompositesWorld.

A. Carbon Fiber: Lightweight, Stiff, and Seriously Strong

Carbon fiber is a high-performance material that offers exceptional strength, lightweight, and excellent durability. However, it can be expensive and require specialized fabrication techniques. According to Chief Delphi, carbon fiber is a good choice for robots that require high performance and exceptional strength.

B. UHMW-PE (Ultra-High Molecular Weight Polyethylene): The Slippery Shield

UHMW-PE is a high-strength and impact-resistant material with excellent durability and corrosion resistance. However, it can be expensive and require specialized fabrication techniques. As noted by Huge BattleBots, UHMW-PE is a good choice for robots that require high performance and exceptional durability.

C. Other Polymer Powerhouses: Delrin, Polycarbonate, and More

Other polymer materials like Delrin and polycarbonate offer unique properties like high strength-to-weight ratio, impact resistance, and corrosion resistance. However, they can be expensive and require specialized fabrication techniques. For more information on polymer materials, check out PlasticsToday.

Beyond the Material: Design Principles for an Indestructible Frame

While the material you choose is crucial, it’s not the only factor in building an indestructible robot frame. Here are some design principles to keep in mind:

- Structural integrity: Ensure your frame has a strong and stable structure that can withstand impacts and stress.

- Geometry and bracing: Use strategic geometry and bracing to distribute stress and absorb impacts.

- Joining forces: Choose the right joining techniques (e.g., welding, bolting, adhesives) to ensure strong bonds between frame components. For more information on design principles, check out Robot Design.

Structural Integrity: Geometry, Bracing, and Stress Distribution

A well-designed frame should have a strong and stable structure that can withstand impacts and stress. Here are some tips for achieving structural integrity:

- Use strategic geometry to distribute stress and absorb impacts.

- Add bracing to reinforce weak points and improve stability.

- Ensure proper alignment and secure fastening of frame components. According to NASA, a well-designed frame is critical for robot performance and safety.

Joining Forces: Welding, Bolting, and Adhesives for Frame Assembly

The joining techniques you use can significantly impact the strength and durability of your robot frame. Here are some options to consider:

- Welding: A strong and permanent joining method, but can be difficult to reverse.

- Bolting: A flexible and reversible joining method, but can be prone to loosening over time.

- Adhesives: A lightweight and corrosion-resistant joining method, but can be weak and prone to failure. For more information on joining techniques, check out Welding.org.

Integrated Armor vs. Structural Frame: A Strategic Showdown

When it comes to protecting your robot, you have two main options: integrated armor or a structural frame. Here are some pros and cons of each approach:

- Integrated armor: Offers enhanced protection and reduced weight, but can be expensive and difficult to fabricate.

- Structural frame: Provides excellent strength and stability, but can be heavy and prone to damage. According to Robot Wrestling League, a well-designed frame is critical for robot performance and safety.

The Bottom Line: Budgeting for Your Battle-Ready Frame

When it comes to budgeting for your robot frame, there are several factors to consider:

- Material costs: The type and quantity of materials you choose will impact your budget.

- Fabrication costs: The complexity and difficulty of fabrication will affect your budget.

- Tooling and equipment costs: The type and quality of tools and equipment you need will impact your budget. For more information on budgeting, check out Behind the Scenes.

Cost vs. Performance: Where to Invest Your Hard-Earned Cash

When it comes to investing in your robot frame, you need to balance cost and performance. Here are some tips for getting the most bang for your buck:

- Prioritize the most critical components and invest in high-quality materials and fabrication.

- Cut costs on non-essential components and consider alternative materials or fabrication methods. According to Chief Delphi, a well-designed frame is critical for robot performance and safety.

Sourcing Smart: Where to Buy Quality Frame Materials

When it comes to sourcing materials for your robot frame, there are several options to consider:

- Online retailers: Amazon, McMaster-Carr, and Grainger offer a wide selection of materials and competitive pricing.

- Local suppliers: Hardware stores, metal suppliers, and fabrication shops can provide convenient and personalized service.

- Specialty stores: Robotics stores, hobby shops, and online forums can offer expert advice and hard-to-find materials. For more information on sourcing materials, check out Opinion Pieces.

Fabrication Finesse: Manufacturing Your Frame Components

When it comes to fabricating your robot frame, there are several techniques to consider:

- CNC machining: Offers high precision and accuracy, but can be expensive and time-consuming.

- Laser cutting: Provides fast and accurate cutting, but can be limited by material thickness and complexity.

- Waterjet cutting: Offers high precision and accuracy, but can be expensive and time-consuming. According to Instructables, a well-designed frame is critical for robot performance and safety.

Cutting Edge Techniques: Laser, Waterjet, and CNC Machining

When it comes to fabricating your robot frame, there are several cutting-edge techniques to consider:

- Laser cutting: Offers fast and accurate cutting, but can be limited by material thickness and complexity.

- Waterjet cutting: Provides high precision and accuracy, but can be expensive and time-consuming.

- CNC machining: Offers high precision and accuracy, but can be expensive and time-consuming. For more information on fabrication techniques, check out Event Announcements.

Hand Tools vs. Machine Shops: What’s Right for Your Build?

When it comes to fabricating your robot frame, you need to decide between hand tools and machine shops. Here are some pros and cons of each approach:

- Hand tools: Offer flexibility and cost-effectiveness, but can be time-consuming and labor-intensive.

- Machine shops: Provide high precision and accuracy, but can be expensive and time-consuming. According to Huge BattleBots, a well-designed frame is critical for robot performance and safety.

Assembly Line Antics: Putting Your Frame Together

When it comes to assembling your robot frame, there are several steps to follow:

- Prepare your components and tools before starting assembly.

- Follow a step-by-step assembly process to ensure accuracy and precision.

- Test and inspect your frame regularly to catch any errors or defects. For more information on assembly, check out Robot Design.

Fasteners and Fixtures: The Unsung Heroes of Robot Construction

When it comes to assembling your robot frame, fasteners and fixtures play a critical role. Here are some tips for choosing the right fasteners and fixtures:

- Choose the right type of fastener (e.g., screws, bolts, nuts) for your specific application.

- Select the right material (e.g., steel, aluminum, plastic) for your fasteners and fixtures.

- Consider the strength and durability of your fasteners and fixtures when designing your frame. According to NASA, a well-designed frame is critical for robot performance and safety.

Welding Wisdom: Tips for Strong, Clean Joints

When it comes to welding your robot frame, there are several tips to follow:

- Choose the right welding technique (e.g., MIG, TIG, ARC) for your specific application.

- Select the right welding equipment (e.g., welder, torch, shielding gas) for your specific application.

- Follow proper welding safety protocols (e.g., welding helmet, gloves, ventilation) to protect yourself and your workpiece. For more information on welding, check out Welding.org.

The Proving Grounds: Testing Your Frame’s Mettle

When it comes to testing your robot frame, there are several steps to follow:

- Prepare your frame and testing equipment before starting testing.

- Conduct a series of tests (e.g., stress, impact, durability) to evaluate your frame’s performance.

- Analyze your test results to identify any weaknesses or areas for improvement. According to Robot Wrestling League, a well-designed frame is critical for robot performance and safety.

Impact Testing and Durability Simulations

When it comes to testing your robot frame, impact testing and durability simulations are essential. Here are some tips for conducting these tests:

- Choose the right testing equipment (e.g., drop tester, impact tester, vibration tester) for your specific application.

- Select the right testing protocol (e.g., ASTM, ISO, MIL-STD) for your specific application.

- Follow proper testing safety protocols (e.g., safety glasses, gloves, ventilation) to protect yourself and your workpiece. For more information on testing, check out Event Announcements.

Post-Battle Analysis: Learning from the Scars

When it comes to analyzing your robot frame’s performance after a competition, there are several steps to follow:

- Inspect your frame for any damage or wear.

- Analyze your competition data (e.g., video, sensor data, telemetry) to identify any weaknesses or areas for improvement.

- Use your analysis to inform your design and fabrication decisions for your next robot frame. According to Huge BattleBots, a well-designed frame is critical for robot performance and safety.

Victory Lap: Enjoying Your Robot and Planning the Next Evolution

When it comes to enjoying your robot and planning your next evolution, there are several steps to follow:

- Celebrate your accomplishments and reflect on your experiences.

- Analyze your competition data (e.g., video, sensor data, telemetry) to identify any weaknesses or areas for improvement.

- Use your analysis to inform your design and fabrication decisions for your next robot frame. For more information on robot design and construction, check out Robot Design.

Conclusion: Forging Your Path to Robot Wrestling Glory

After an in-depth exploration of the best materials for building a robot wrestling frame, it’s clear that there’s no one-size-fits-all answer. Your choice depends heavily on your robot’s weight class, budget, fabrication capabilities, and performance goals.

Positives and Negatives of Top Materials Reviewed:

| Material | Positives | Negatives |

|---|---|---|

| 6061-T6 Aluminum | Lightweight, easy to machine and weld, cost-effective | Less impact-resistant, can deform under heavy hits |

| 7075-T6 Aluminum | Higher strength than 6061, excellent strength-to-weight | Difficult to weld/form, more expensive |

| Mild Steel (1018, A36) | Durable, cheap, easy to weld and machine | Heavy, prone to corrosion without treatment |

| HSLA Steel | Stronger and lighter than mild steel, corrosion-resistant | More expensive, requires skilled welding |

| Chromoly (4130 Steel) | Excellent strength-to-weight, tough and durable | Expensive, requires specialized fabrication |

| Grade 5 Titanium (Ti-6Al-4V) | Exceptional strength-to-weight, corrosion-resistant | Very expensive, difficult to machine/weld |

| Carbon Fiber | Ultra-lightweight, stiff, impact-resistant | Expensive, brittle under certain impacts, complex fabrication |

| UHMW-PE | Impact-resistant, lightweight, easy to machine | Lower structural strength, can deform under load |

Our Confident Recommendation:

For most robot wrestling enthusiasts competing in the Robot Wrestling League™, 6061-T6 aluminum strikes the best balance between weight, strength, and fabrication ease. If your budget and fabrication resources allow, 7075-T6 aluminum or chromoly steel are excellent upgrades for increased durability without excessive weight penalty. For elite builds, Grade 5 titanium and carbon fiber composites offer cutting-edge performance but require specialized skills and investment.

Remember, the frame material is the backbone of your robot. Combine smart material choices with solid design principles and quality fabrication to build a frame that can take a beating and keep fighting. As we teased earlier, the best material is the one that fits your unique design goals and constraints — now you have the knowledge to make that call confidently!

Recommended Links: Your Arsenal of Robot Building Resources

👉 Shop Materials and Tools:

- 6061-T6 Aluminum: Amazon | McMaster-Carr | Alcoa Official Website

- 7075-T6 Aluminum: Amazon | McMaster-Carr

- Mild Steel (1018, A36): Amazon | Grainger

- Chromoly Steel (4130): Amazon | Online Metals

- Grade 5 Titanium (Ti-6Al-4V): Titanium Metals Corporation | Amazon

- Carbon Fiber Sheets: Amazon | Rock West Composites

- UHMW-PE Sheets: Amazon | McMaster-Carr

Recommended Books:

- Robot Builder’s Bonanza by Gordon McComb — A classic guide packed with practical tips on robot construction.

- Materials Science and Engineering: An Introduction by William D. Callister — For those who want to dive deep into material properties.

- Welding For Dummies by Steven Robert Farnsworth — Essential for mastering welding techniques.

FAQ: Your Burning Questions About Robot Frame Materials Answered

What are the strongest metals for constructing a robot wrestling frame?

Steel alloys like chromoly (4130) and high-strength low-alloy (HSLA) steels are among the strongest metals commonly used in robot frames. They offer excellent impact resistance and durability, essential for absorbing the brutal hits in robot wrestling. Grade 5 titanium is even stronger relative to its weight but comes at a premium cost and fabrication complexity.

How does aluminum compare to steel for robot wrestling frames?

Aluminum alloys, especially 6061-T6 and 7075-T6, are significantly lighter than steel, offering a better strength-to-weight ratio. However, aluminum tends to deform under heavy impacts more easily than steel. Steel is heavier but provides superior toughness and durability. The choice depends on whether you prioritize weight savings or maximum impact resistance.

What lightweight materials are ideal for competitive robot wrestling?

Aluminum alloys and carbon fiber composites are the go-to lightweight materials. Aluminum is easier to machine and weld, while carbon fiber offers exceptional stiffness and strength at a fraction of the weight but requires specialized fabrication. UHMW-PE is also used for non-structural components due to its impact resistance and low weight.

Read more about “How Much Does It Cost to Build a Competitive Robot Wrestler? 🤖 (2025)”

Can carbon fiber be used effectively in robot wrestling frame designs?

Yes, but with caveats. Carbon fiber is extremely stiff and lightweight, making it excellent for frame panels or armor. However, it is brittle under sharp impacts and can delaminate if not properly engineered. It’s best used in combination with metal frames or in less impact-prone areas. Many top teams use carbon fiber for armor panels rather than the primary structural frame.

What are the pros and cons of using titanium in robot wrestling frames?

Pros: Titanium alloys like Grade 5 Ti-6Al-4V offer an excellent strength-to-weight ratio, corrosion resistance, and fatigue strength.

Cons: Titanium is very expensive, hard to machine and weld, and requires specialized tools and expertise. It’s often reserved for elite-level robots or critical components like drive shafts and armor.

How do material choices affect the durability of robot wrestling frames?

Material choice directly impacts how well your frame absorbs impacts, resists deformation, and survives repeated battles. Metals like steel and titanium provide high durability but can add weight. Aluminum offers weight savings but may require thicker sections or reinforcements. Composites provide lightweight protection but may fail catastrophically if overstressed.

What materials do top Robot Wrestling League competitors use for their frames?

Top competitors often use a combination of materials:

- Chromoly steel or HSLA steel for the main structural frame for toughness.

- 7075-T6 aluminum for substructures and mounts to save weight.

- Titanium for critical components like drive shafts or armor panels.

- Carbon fiber and UHMW-PE for armor and impact absorption.

This hybrid approach balances strength, weight, and cost effectively.

Reference Links: Dive Deeper into Material Science

- Aluminum Association: Aluminum Alloys

- Steel Manufacturers Association

- Titanium Metals Corporation

- McMaster-Carr: Raw Materials

- NASA Material Properties

- Instructables: How to Design and Build a Combat Robot

- Huge BattleBots Build Log 2018 Season

- Robot Wrestling League Official Site

With this comprehensive guide, you’re now equipped to choose the perfect material and design a frame that will dominate the arena. Ready to build your champion? Let’s get welding, cutting, and assembling! 🛠️🤖